Krátký popis produktu:

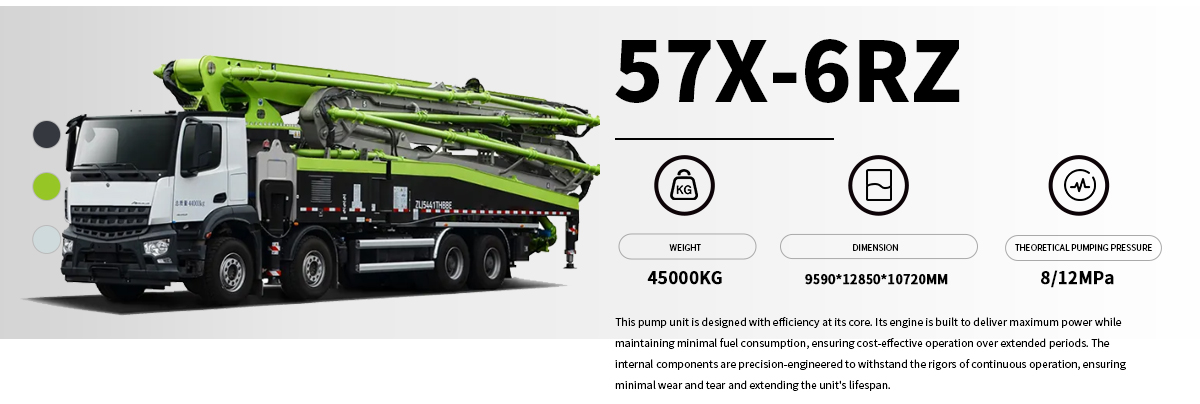

Tato čerpací jednotka je navržena s důrazem na účinnost. Jeho motor je konstruován tak, aby poskytoval maximální výkon při zachování minimální spotřeby paliva, což zajišťuje nákladově efektivní provoz po dlouhou dobu. Vnitřní komponenty jsou precizně navrženy tak, aby vydržely náročné podmínky nepřetržitého provozu, zajišťují minimální opotřebení a prodlužují životnost jednotky.

Parametrická specifikace:

| Model Č. |

Zoomlion 57X-6RZ |

Typ |

Betonové čerpadlo |

| Typ stříkaného betonu |

Polosuché |

Proces obrábění |

Hydraulický |

| certifikace |

ISO9001: 2000, CE |

Produktivita |

125 |

| Vertikální výška |

56,25 m |

Horizontální délka |

52,25 m |

| Teoretický čerpací tlak |

8/12 MPa |

Hydraulický systém |

Otevřít |

| Fixní pracovní stres |

35 MPa |

Frekvence čerpání |

25 min-1 |

| Vrtání betonu X zdvih |

Rozměr 260 x 2100 mm |

Maximální tkanina (H/R/D) |

46,1/41,8/32,2 |

| Objem |

12,8 l |

Maximální výstupní tlak betonu |

8/13 MPa |

| Maximální teoretická přepravní kapacita |

125/75 m³/H |

Specifikace |

9590*12850*10720mm |

| Hmotnost |

45000 |

stav |

Nový |

Hlavní vlastnosti:

● Jednou z výjimečných vlastností této čerpací jednotky je její agilní výložník. Je vhodný pro širokou škálu pracovních prostředí, a to i těch s výškovým omezením. Tato kompaktní konstrukce umožňuje snadnou manipulaci s čerpací jednotkou ve stísněných prostorech, což zajišťuje maximální všestrannost na pracovišti.

● Jednostranná boční podpora je další pozoruhodnou vlastností této čerpací jednotky. Tato inovativní konstrukce umožňuje efektivní provoz v úzkých prostorách, kde by tradiční čerpací jednotky mohly mít potíže. Tato nosná konstrukce stabilizuje jednotku a zajišťuje přesné a přesné umístění materiálů i ve stísněných prostorách.

● Prostřednictvím konstrukce hřídele, vnější konstrukce ojnice, malé boční třesy, vysoká pevnost, tuhost, bezpečné a spolehlivé.

● Nová čerpací jednotka s nízkým odporem, uspořádání betonového potrubí, návrh optimálního sklonu, nízký odpor, více nasávání materiálu, technologie rozpoznávání stavu betonového materiálu pro efektivní zatížení, automatická identifikace dobrého materiálu, aktivní kontrola blokování potrubí, průtok betonu "bez omezení".

● Doba expanze výložníku je výrazně zkrácena, o 15 % rychlejší než na průmyslové úrovni, a efektivita konstrukce je vysoká.

● Hadice na konci výložníku je v zadní části vozidla a čištění potrubí dopravníku nevyžaduje výložník, což je pohodlné a rychlé.

Aplikace:

Jako ideální použití pro vysokopodlažní čerpadla na beton můžete získat vysoce výkonnou dodávku materiálu v úzkých prostorách a vyvýšených místech, což umožňuje rychlejší návratnost investice.

Dobře se hodí pro čerpání betonu do vyšších pater budovy pro stěny a sloupy, stejně jako základy, paluby, parkovací konstrukce atd.