Maikling paglalarawan ng produkto:

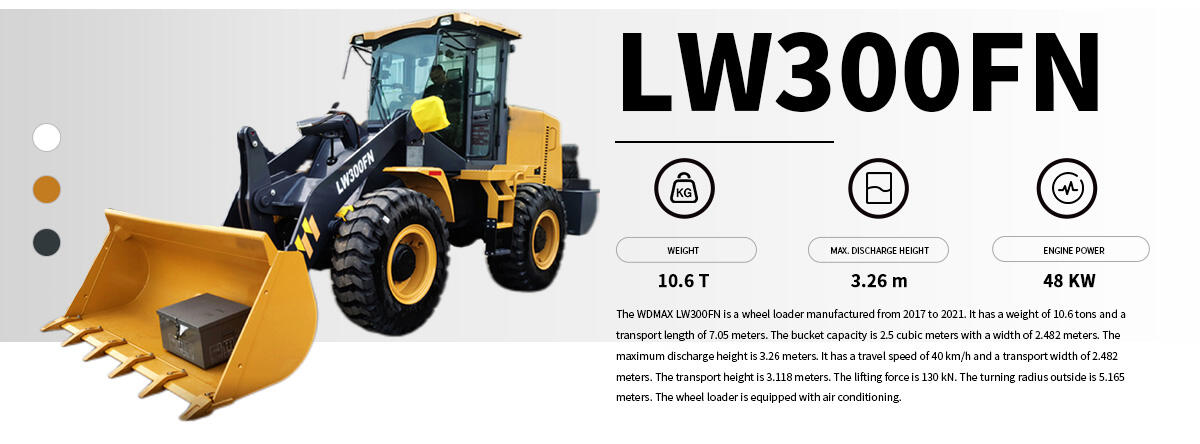

Ang WDMAX LW300FN ay isang wheel loader na ginawa mula 2017 hanggang 2021. Ito ay may timbang na 10.6 tonelada at 7.05 metro ang haba ng transportasyon. Ang kapasidad ng balde ay 2.5 metro kubiko na may lapad na 2.482 metro. Ang maximum na taas ng pag-alis ay 3.26 metro. Ito ay may bilis ng paglalakbay na 40 km/h at isang lapad ng transportasyon na 2.482 metro. Ang taas ng transportasyon ay 3,118 metro. Ang lakas ng pag-angat ay 130 kN. Ang radius ng pagliko sa labas ay 5,165 metro. Ang wheel loader ay may air conditioning.

Mga detalye ng parameter:

|

Timbang

|

max. taas ng pag-alis

|

Lakas ng makina

|

|

10.6 t

|

3.26 m

|

48 kW

|

|

Mga standard na gulong

|

Pag-ikot ng radius sa labas

|

Max. torque

|

|

17.5-25-12PR

|

5.165 m

|

305/1500 Nm

|

|

lapad ng timba

|

Pananatili ng lakas ng pag-angat

|

bilis ng paglalakbay

|

|

2.482 m

|

130 kN

|

40 km/h

|

|

Kapasidad ng timba

|

Seryeng modelo

|

Hab ng Transport

|

|

2.5 m³

|

LW

|

7.05 m

|

|

Kapasidad ng balde min.

|

Paggawa ng makina.

|

Luad ng transportasyon

|

|

2.5 m³

|

Kohler

|

2.482 m

|

|

Modyo ng pag-steering

|

Uri ng Motor

|

Taas ng transportasyon

|

|

KL

|

KDI2504

|

3.118 m

|

Mga Pangunahing katangian:

Mga Karakteristika ng Modelo

● Ito ay may mataas na kahusayan, hindi nag-iimpake ng enerhiya, at malakas na kapangyarihan.

● Ang tatlong-element torque converter at ang fixed shaft power shift transmission ay may mataas na pagkalaki at pagiging maaasahan.

● Ang 2600mm wheelbase ay nagtatampok ng mataas na paggalaw at kakayahang umangkop at naaangkop sa lahat ng uri ng mga lugar ng trabaho.

● Ang balde ay gawa sa mataas na lakas ng materyal upang makamit ang mataas na pagkalason at paglaban sa pag-atake.

● Ang iba't ibang mga configuration at kumpletong mga kasangkapan ay nababagay sa mga pangangailangan sa pagtatayo sa iba't ibang rehiyon at sa iba't ibang mga kundisyon sa pagtatrabaho.

● Ang opsyonal na A/C at ang sound insulation at noise reduction measure ay may mahusay na paraan upang makabuo ng komportable na kapaligiran sa pagtatrabaho.

Mga Pinakamahalagang Lumang Nagawa

● Napakalaking kakayahan, na may traction sa ≥9t at break-out force sa ≥13t.

● Mataas na kakayahang umangkop, na may radius ng pag-ikot na 5,165mm (pulo ng gulong).

● Ang tangke ng diesel ay nadagdagan ng 17%, at ang saklaw ng buong makina ay nadagdagan ng 2 oras.

Mga aplikasyon:

Ang iba't ibang mga naka-attach na tool na nakakatugon sa mga kinakailangan ng iba't ibang mga kondisyon ng pagtatrabaho.

Clamp: Para sa pag-aari at transportasyon ng iba't ibang mga kahoy at tubo.

Bale grabber: Ginagamit ito para sa pag-aari at paghawak ng iba't ibang magaan na mga materyales sa mga bukid, biological power plant, at mga pabrika ng papel.